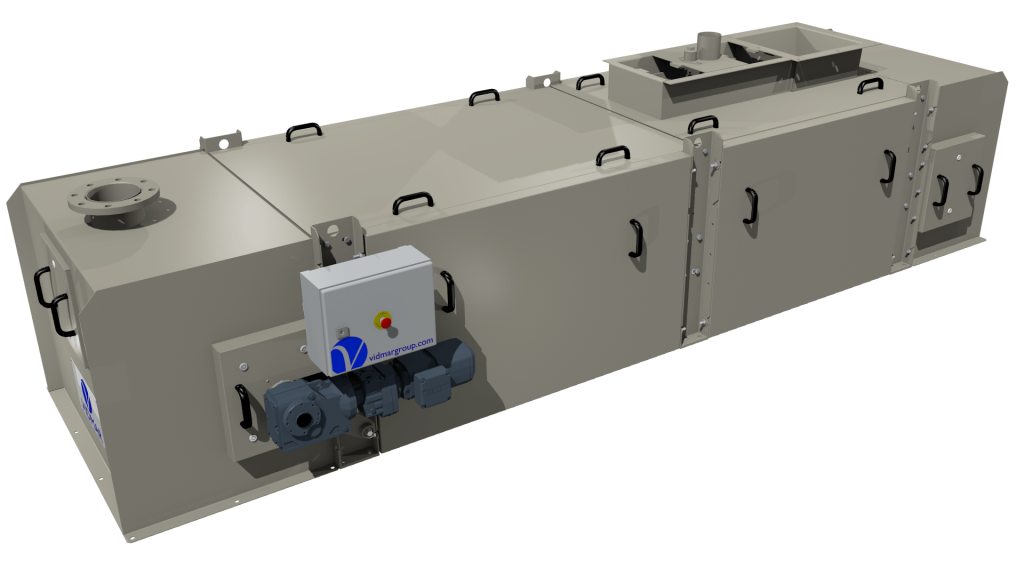

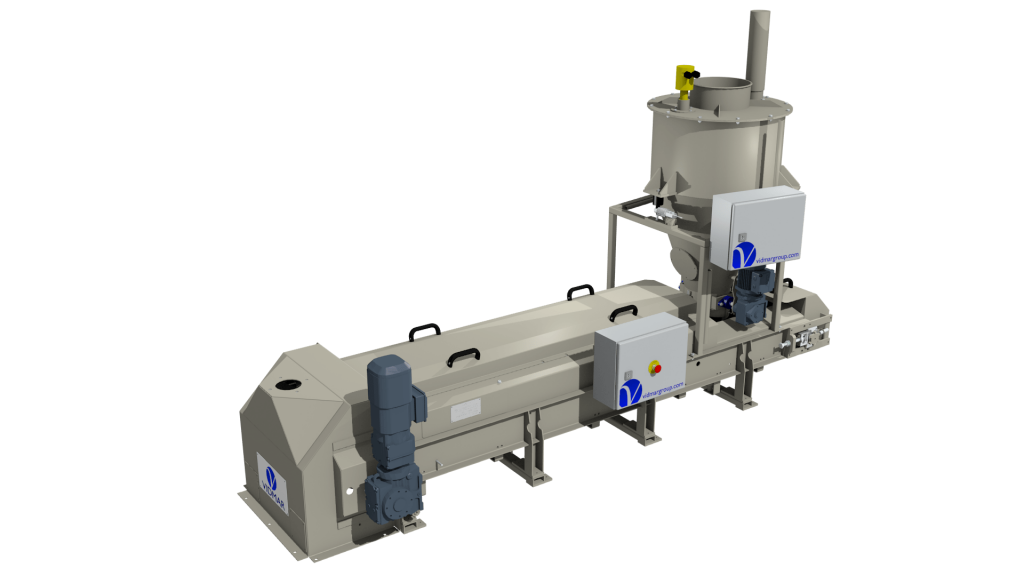

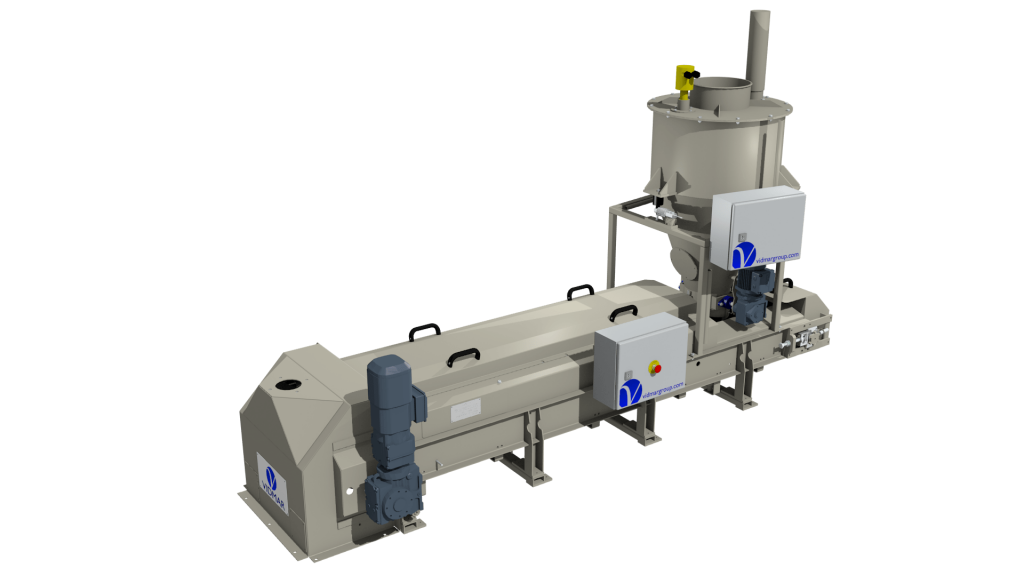

BMG Serie

Equipment for the gravimetric dosing of granular products. Robust design and ready to work with large loads. It can be installed directly under silos with vertical, divergent or mass flow wall design. Manufactured in different materials according to the application. The primer and the finishing paint can be made according to the customer’s specifications. The use of direct coupling drives, orthogonal type, hollow shaft, with motors of alternating current, guarantees an optimal transmission of power.

The use of world leading brand components guarantees the reliability of the belt weigh feeders.

Applications

- Dosing of granular products in large flows rates.

- Dosing of products with temperatures of up to 200ºC in continuous.

- Specific designs for the dosing of alternative fuels and very low density products.

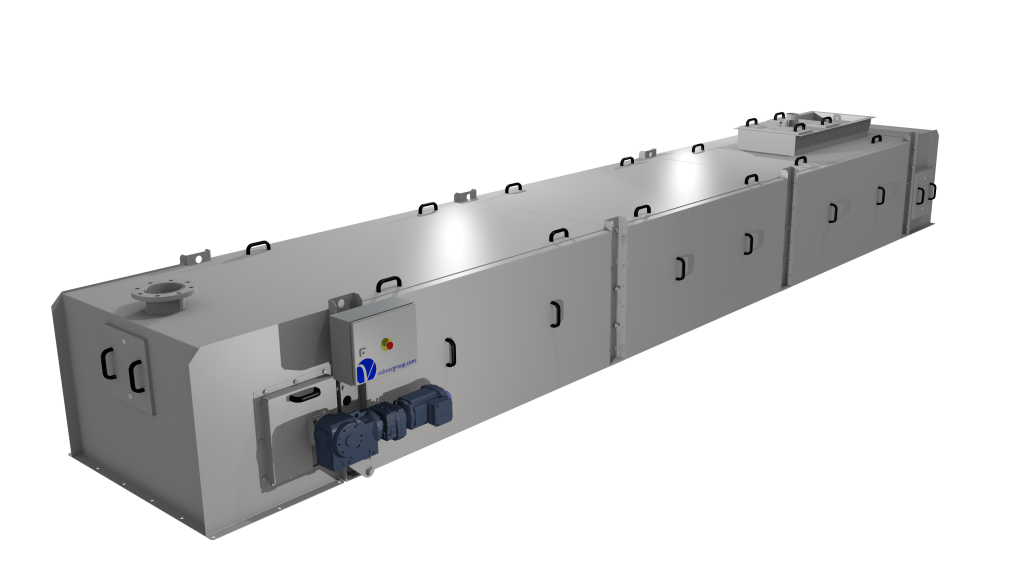

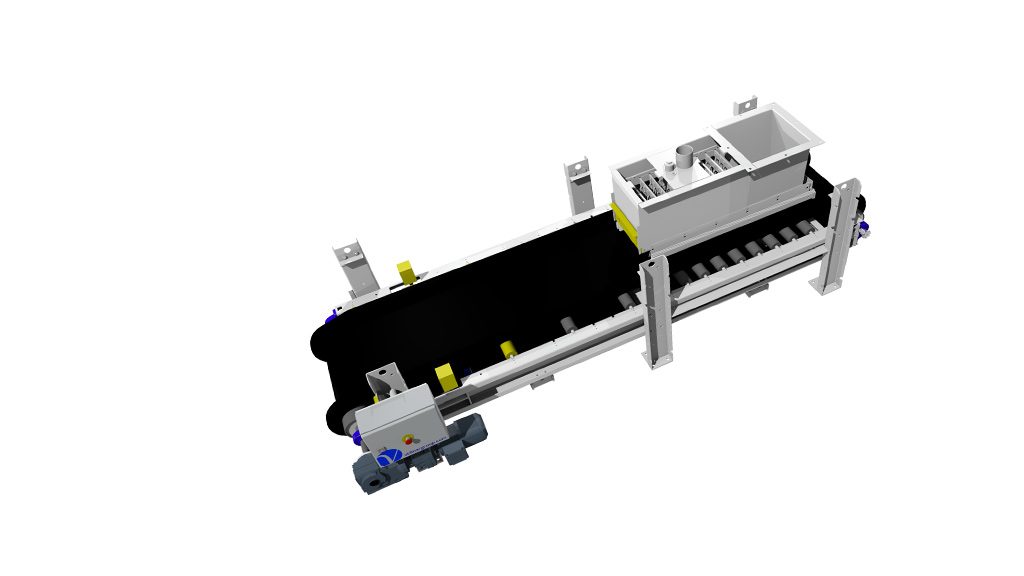

BWG Serie

Equipment for the gravimetric dosing of granular products. Robust design and ready to work with medium loads. It can be installed directly under silos with vertical, divergent or mass flow wall design. Manufactured in different materials according to the application. The primer and the finishing paint can be made according to the customer’s specifications. The use of direct coupling drives, orthogonal type, hollow shaft, with motors of alternating current, guarantees an optimal transmission of power.

The use of world leading brand components guarantees the reliability of the belt weigh feeders.

Applications

- Dosing of granular products in medium flows rates.

- Dosing of products with temperatures of up to 200ºC in continuous.

- Specific designs for the dosing of alternative fuels and very low density products.

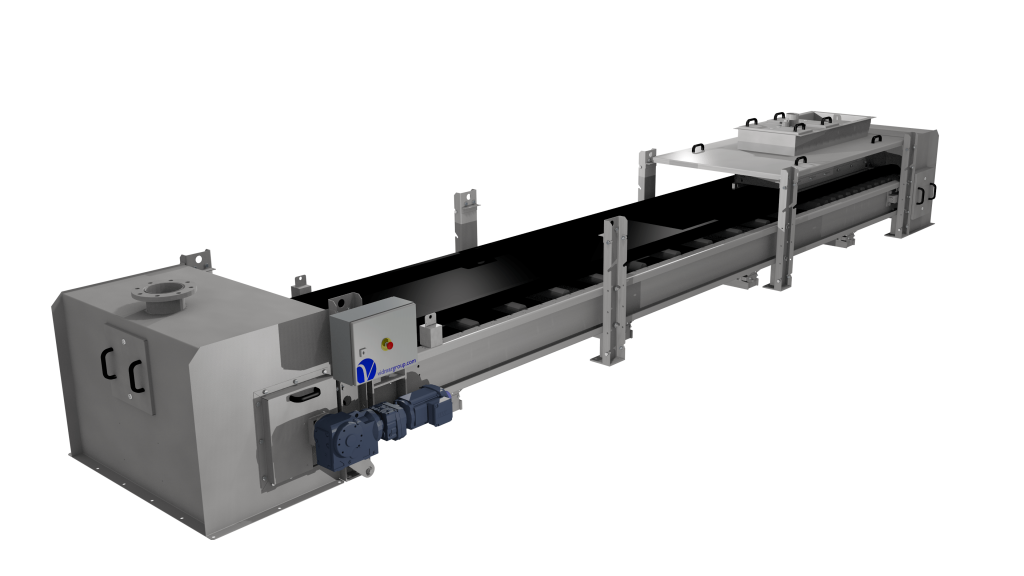

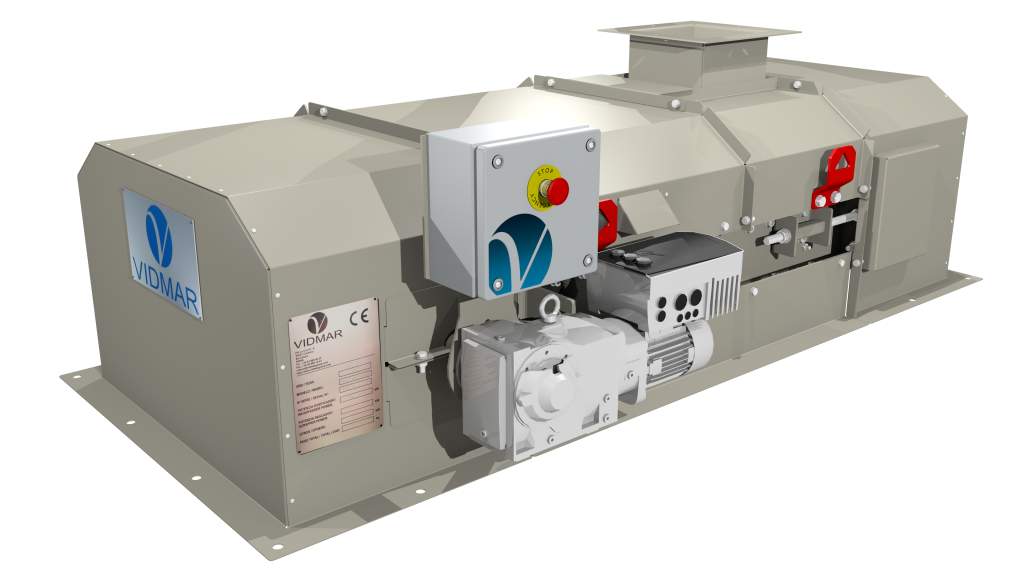

HG Serie

Equipment for the gravimetric dosing of granular products. Robust design and ready to work with small loads. It can be installed directly under silos with vertical, divergent or mass flow wall design. Manufactured in different materials according to the application. The primer and the finishing paint can be made according to the customer’s specifications. The use of direct coupling drives, orthogonal type, hollow shaft, with motors of alternating current, guarantees an optimal transmission of power.

The use of world leading brand components guarantees the reliability of the belt weigh feeders.

Applications

- Dosing of granular products in small flows rates.

- Dosing of products with temperatures of up to 200ºC in continuous.

- Specific designs for the dosing of alternative fuels and very low density products.

PowdersBWP Series

Equipment for gravimetric dosing of powdered products. It has a flange for the connection of a previous feeder (rotary valve, sector gate, etc.). Robust design and watertight equipment that in its intake hopper incorporates a material soothing chamber, which ensures a continuous and constant supply of material to the weighing bridge. Made of different materials depending on the application. Primer and finish paint can be made according to customer’s specifications. The use of direct coupling drives, orthogonal type, hollow shaft, with AC motors, ensures optimal power transmission.

The use of world leading brand components guarantees the reliability of the dosing scale.

Applications

- Dosing of medium and large powder products flows.

- Dosing of products with temperatures of up to 200ºC in continuous.

- Application for dosing of fly ash, crude flour for production of clinker, cement, coal, feldspar, clays, all types of flours and any product with little slope and very small granulometry.

Microdosing EquipmentEquipment for the gravimetric dosing of granular or pulverulent products in small flow rates. Robust design and ready to work with products with aggressive physical properties (corrosion, humidity, etc.). Manufactured in different materials according to the application. The primer and the finishing paint can be made according to the customer’s specifications. The use of direct coupling drives, orthogonal type, hollow shaft, with AC motors ensure an optimal power transmission.

The use of world leading brand components guarantees the reliability of the dosing scale.

Applications

- Dosing of additives

- Dosing of powdery products

- Dosing of hygroscopic products

Belt weigh feeder for alternative fuelsBAF Serie

Belt feeder specially designed for the dosing of low density products such as alternative fuels: RDF, TDF, biomass, plastics, paper, olive pomace, etc.

Robust design prepared to work with medium and small loads. Manufactured in different materials according to the application.

Aplicaciones

- Integral solutions for the dosing and selection of alternative fuels, coming from urban garbage, industrial waste, tires or oil residues.

- Feeding for cement kilns or similar.

- Turnkey supply of complete plants. Mechanical, electrical installation and control system.

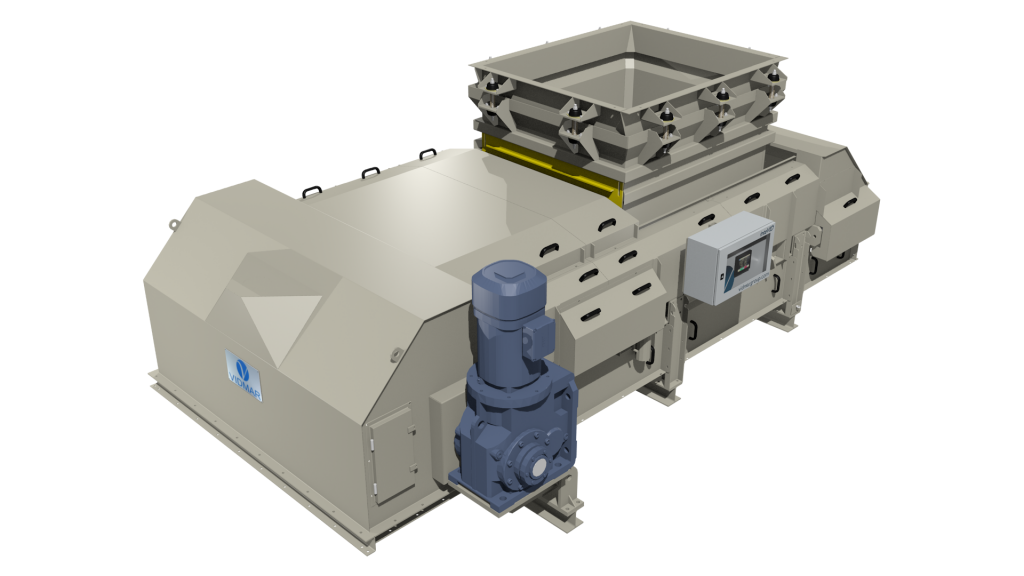

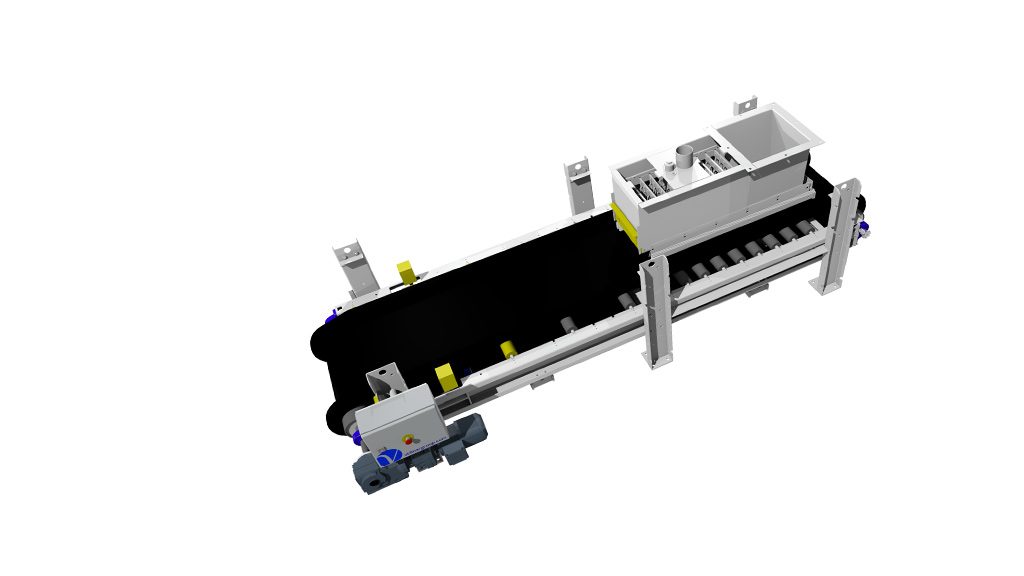

BWP Series

Equipment for gravimetric dosing of powdered products. It has a flange for the connection of a previous feeder (rotary valve, sector gate, etc.). Robust design and watertight equipment that in its intake hopper incorporates a material soothing chamber, which ensures a continuous and constant supply of material to the weighing bridge. Made of different materials depending on the application. Primer and finish paint can be made according to customer’s specifications. The use of direct coupling drives, orthogonal type, hollow shaft, with AC motors, ensures optimal power transmission.

The use of world leading brand components guarantees the reliability of the dosing scale.

Applications

- Dosing of medium and large powder products flows.

- Dosing of products with temperatures of up to 200ºC in continuous.

- Application for dosing of fly ash, crude flour for production of clinker, cement, coal, feldspar, clays, all types of flours and any product with little slope and very small granulometry.

Equipment for the gravimetric dosing of granular or pulverulent products in small flow rates. Robust design and ready to work with products with aggressive physical properties (corrosion, humidity, etc.). Manufactured in different materials according to the application. The primer and the finishing paint can be made according to the customer’s specifications. The use of direct coupling drives, orthogonal type, hollow shaft, with AC motors ensure an optimal power transmission.

The use of world leading brand components guarantees the reliability of the dosing scale.

Applications

- Dosing of additives

- Dosing of powdery products

- Dosing of hygroscopic products

Belt weigh feeder for alternative fuelsBAF Serie

Belt feeder specially designed for the dosing of low density products such as alternative fuels: RDF, TDF, biomass, plastics, paper, olive pomace, etc.

Robust design prepared to work with medium and small loads. Manufactured in different materials according to the application.

Aplicaciones

- Integral solutions for the dosing and selection of alternative fuels, coming from urban garbage, industrial waste, tires or oil residues.

- Feeding for cement kilns or similar.

- Turnkey supply of complete plants. Mechanical, electrical installation and control system.

BAF Serie

Belt feeder specially designed for the dosing of low density products such as alternative fuels: RDF, TDF, biomass, plastics, paper, olive pomace, etc.

Robust design prepared to work with medium and small loads. Manufactured in different materials according to the application.

Aplicaciones

- Integral solutions for the dosing and selection of alternative fuels, coming from urban garbage, industrial waste, tires or oil residues.

- Feeding for cement kilns or similar.

- Turnkey supply of complete plants. Mechanical, electrical installation and control system.